James Bonham and Arlen Hurt review innovations in 3D-printing technologies

3D printing continues to march forward in what many experts call the next industrial revolution. Also known as additive manufacturing, 3D printing is the process for making a physical object from a three-dimensional digital model file by laying down successive thin layers of a material. 3D-printing technology is changing the way products and prototypes are produced in every industry, including advancements in the dental industry. The purpose of this article is to review several common 3D-printing technologies used in today’s dental market.

3D printing continues to march forward in what many experts call the next industrial revolution. Also known as additive manufacturing, 3D printing is the process for making a physical object from a three-dimensional digital model file by laying down successive thin layers of a material. 3D-printing technology is changing the way products and prototypes are produced in every industry, including advancements in the dental industry. The purpose of this article is to review several common 3D-printing technologies used in today’s dental market.

3D printers rely on 3D scanners and CAD software to create and manipulate printable data files. 3D scanners can be direct or indirect. Direct scanners are in contact with the object, while indirect scanners gather information with the scanner away from the object. Most dental scanners use the indirect capture technique. All scanners are prone to missing data and rely on CAD software to fill the voids of missing data. It is always important to carefully review your dental scans for accuracy prior to starting the printing process.

After the scan data has been captured, the 3D model files need to be sealed and identified before it can be sent to the 3D printer. A third-party additive printing software such as Netfabb® is used for printer preparation. The 3D printer’s software then slices the model file into very small layers. These thin layers are then reconstructed during the printing process. Printers vary in their resolution capabilities. High-resolution printers will lay thinner layers and produce a surface that is smoother than low-resolution printers.

There are multiple additive printing technologies available, including Vat Photo-polymerization (light polymerization), Material Jetting, Binder Jetting, Material Extrusion, Powder Bed Fusion, Sheet Lamination, and Directed Energy Deposition. At Specialty Appliances laboratory, we currently use three different 3D-printing technologies to fabricate dental models. Each technology has strengths and weaknesses that we will discuss.

VAT Polymerization

The first type of light polymerization that we use is stereolithography (SLA or SL). Stereolithography is an additive manufacturing process that works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin. This process creates parts when a laser passes over the resin, using photo polymerization to cure each layer. SLA advantages include a relatively fast print speed. Printed models are strong and make great master molds. Disadvantages of SLA printing include a higher cost of ownership, and post-processing requires a chemical bath before being placed in a UV curing oven.

The first type of light polymerization that we use is stereolithography (SLA or SL). Stereolithography is an additive manufacturing process that works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin. This process creates parts when a laser passes over the resin, using photo polymerization to cure each layer. SLA advantages include a relatively fast print speed. Printed models are strong and make great master molds. Disadvantages of SLA printing include a higher cost of ownership, and post-processing requires a chemical bath before being placed in a UV curing oven.

Another VAT Polymerization technology is Digital Light Projection (DLP). DLP technology is used in cinemas, classrooms, and in rear projection televisions. In 3D printing, this energy source is projected onto a photo polymer to create 3D models. DLP technology exposes one complete layer in a single shot, creating much faster print times compared to point-by-point technologies. The layer thickness is adjustable to sub-50 µm resolution on the image plane. DLP printing shares the same advantages as SLA printing, but it is faster and offers a lower cost of ownership. Disadvantages of DLP technology include the same chemical bath and UV curing for post-processing as with SLA technology.

Material Jetting

Material Jetting

This process is very similar to an inkjet printer, but the print head drops photopolymers instead of ink. Two materials are used in this process. A build material is accompanied by a filler material to help create difficult geometries. A UV light cures both materials as their layers are dropped. Post- processing involves soaking the model, then using a high-powered water jet station to remove the fill material. Material jetting has advantages such as consistent accuracy, and no chemicals are necessary for post-processing. Multiple materials can also be incorporated in a single print job. Disadvantages include a noisy and technique sensitive pressure washer for post-processing. The material cost is higher than any other 3D-printing technologies covered in this article.

Material Extrusion

Material Extrusion

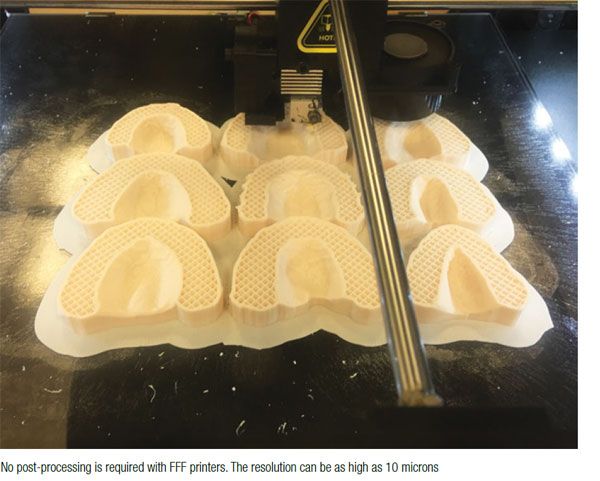

Material Extrusion is also referred to as FFF (Fused Filament Fabrication). Parts are produced by extruding small beads of melted material, which harden immediately to form object layers. A spool of hermoplastic filament is unreeled to supply material to an extrusion nozzle head. The nozzle head heats the material and turns the flow on and off. Typically stepper motors are used to move the extrusion head and adjust the flow of material as the layers are placed. Advantages include a wide range of materials and the lowest cost of ownership. There is also no post-processing required for FFF printers. Disadvantages include visible layer lines and longer build times compared to other printing technologies. Temperature fluctuations during production can cause issues like delamination.

To learn more about 3D printing for your orthodontic office, contact Specialty Appliances.

James Bonham is a partner at Specialty Appliances and manages sales and marketing. He has spent the past 12 years in orthodontics with a strong focus on the integration of digital technology into orthodontic practices.

James Bonham is a partner at Specialty Appliances and manages sales and marketing. He has spent the past 12 years in orthodontics with a strong focus on the integration of digital technology into orthodontic practices.

As Vice President and partner at Specialty Appliances, Arlen Hurt, CDT, has dedicated the past 30 years to orthodontic appliance innovation. Mr. Hurt is recognized as an award-winning inventor, published author, and national orthodontic speaker. He is best known as one of the most dependable resources for orthodontists everywhere.

As Vice President and partner at Specialty Appliances, Arlen Hurt, CDT, has dedicated the past 30 years to orthodontic appliance innovation. Mr. Hurt is recognized as an award-winning inventor, published author, and national orthodontic speaker. He is best known as one of the most dependable resources for orthodontists everywhere.

Stay Relevant With Orthodontic Practice US

Join our email list for CE courses and webinars, articles and mores