CEU (Continuing Education Unit): 2 Credits

Educational aims and objectives

This self-directed educational course for dentists provides information for those who have interest in building or expanding their knowledge regarding applications of in-house 3D printing.

Expected outcomes

Orthodontic Practice US subscribers can answer the CE questions by taking the quiz to earn 2 hours of CE from reading this article. Correctly answering the questions will demonstrate the reader can:

- Identify the elements involved in choosing a 3D printer in orthodontics.

- View examples of how a combination of 3D printing and digital orthodontics can be used, and identify where and how to increase the capacity of your 3D printing lab and adapt digital orthodontics.

- Review the current research behind 3D printing in orthodontics.

- Identify the future prospects for 3D printing in orthodontics.

Dr. Sunny Jisun Lee outlines how 3D printing can benefit the orthodontic practice

The utilization of 3-dimensional printing in dental settings has experienced significant growth in recent years. In particular, its implementation in orthodontic offices has gained attention due to its extensive and versatile range of applications. The extent to which an orthodontist incorporates 3D printing into their practice naturally depends on factors such as software, printing technology, available human resources, and importantly, their treatment philosophy. The applications highlighted in this article reflect only a portion of what 3D printers can achieve in orthodontics. Nonetheless, they can serve as a guiding example for those who are starting or expanding their in-house lab, regardless of its size.

Selecting a printer

Choosing the right printer has an enormous financial and clinical impact on the office. The following should be considered:

- Cost

- Time-efficiency

- Accuracy

- Print volume for practice

One thing to note is that although different types of printing technologies do influence the accuracy of 3D printed models, it does not make a significant change in clinical outcomes1 — in other words, you can use any known type of 3D printer and trust that they will render clinically acceptable models. However, we will later address other factors that will affect the clinical outcomes.

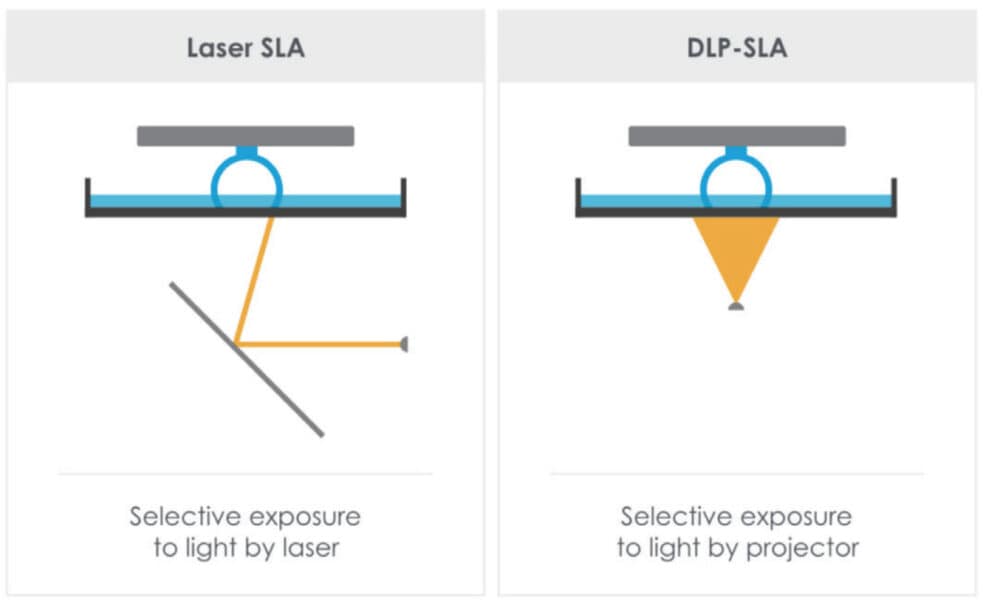

The two most popular printing technologies in current orthodontics are undoubtedly laser-stereolithography (SLA) and digital light processing (DLP) — both being relatively affordable but not compromising on accuracy. They belong to the vat polymerization printer category, which involves using liquid resin and a curing light to solidify the resin. Between these two, DLP is considered to offer a better balance between cost and efficient printing.2 Faster than laser-SLA, DLP’s speed comes from the fact the digital light projector projects the given cross-sectional area all at once (Figure 1). Having an advanced laser chip (e.g., a true 4k processing chip) that provides high pixel density reduces the stair-stepping effect, ensuring a smooth surface and increased clarity.

When evaluating the cost-benefit analysis, one must consider additional costs associated with printers. Both laser-SLA and DLP printers require an alcohol wash and post-cure process. Resin is typically sold in liters, and manufacturers usually recommend purchasing resin from the same brand for warranty and proper servicing. Lastly, servicing cost and period are commonly overlooked, but keep in mind that most printers will require regular maintenance and may need occasional emergency servicing. Therefore, high-volume practices will benefit from owning more than one working printer. Those who own smaller practices or have longer turnover time for resin use should pay attention to the expiration date and shelf life for resin.

Our offices use DLP printers: Desktop Health’s Envision TEC Vida2 and Envision One as well as the Einstein Pro XL. As mentioned above, the Pro XL with an advanced DLP chips claims to mitigate the stair-stepping effect by precisely managing the light intensity along the contours of a design (Figure 2). Considering its pricing range of $15k-40k, it is likely that they are positioned at a higher range compared to what most dental offices have. Again, it becomes imperative to carefully assess the cost and benefits when selecting a printer.

Products of 3D printing

Models

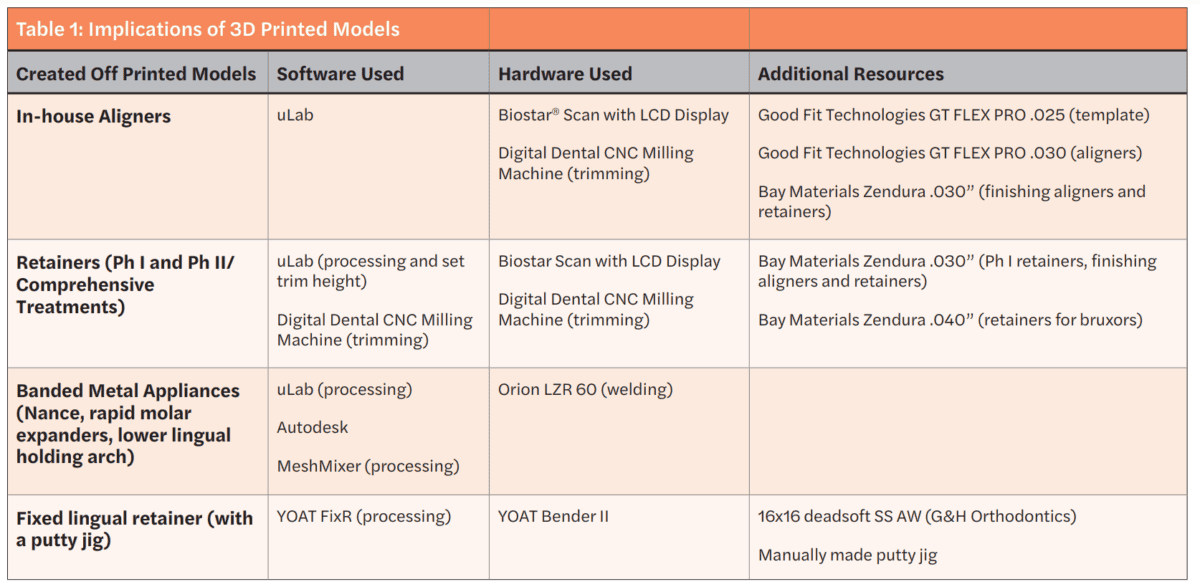

- The choice of software for model processing is an important consideration as some software provides more features than others. Having a consistent system in place leads to higher efficiency and reduces confusion for staff. Please refer to the section “Further Implications of Printed Models” for a list of software and hardware we utilize.

- When it comes to determining the appropriate layer height for a clinically acceptable printed model, research consistently demonstrates that a 100-µm layer is superior to 25-µm or 50-µm layers.5 Therefore, a 100-µm layer height seems to be the minimum when deciding on the layer height for printing.

- Current research suggests the orientation of printed arches does not significantly affect the accuracy of 3D-printed models for aligner purposes.6 Although my office has been printing arches horizontally, we are currently testing the vertical orientation for increased printing efficiency.

Indirect bonding (IDB) trays

- Despite research findings, multiple-tray printing (MTP) appears to be the clinical winner. Single-tray printing (STP) has demonstrated fewer errors in bracket positioning compared to MTP7 — however, STP faces two big challenges in the clinic. First, removing a single tray that covers the entire arch after curing becomes difficult for patients who present crowding and/or buccal inclination of incisors. Second, if IDB was performed poorly, it may result in failure and debonding of the entire arch instead of small segments (Figure 3). These challenges make MTP a more practical and clinically feasible option for many orthodontic practices.

- IDB software from other companies may draw attention for their unique features — such as a channel that allows cleaning up around brackets or ability to self-process trays.

In-house aligners

- The impact of trim design on tooth movement with aligners is widely acknowledged.8 In my office, we have a specific approach to trim design. Instead of utilizing a scalloped design, we trim most aligners to a height of 0.5 mm above the gingiva to prioritize patient comfort. For patients who require non-compliance or have challenging tooth movements, we increase the trim height to 0.75 mm. In cases of gingival recession or abfraction, aligners are trimmed at the cemento-enamel junction (CEJ).

- To mark the trimline, we employ uLab software, although it should be noted that manual marking introduces the potential for human error. For the actual trimming process, we rely on a milling machine specifically designed for trimming aligners and retainers. This enables our staff to efficiently and effectively prepare the aligners, ensuring a precise and comfortable fit for our patients.

Retainers

- Ph I retainers cover U2-2 and U6’s with palatal coverage. All other retainers are made with a full coverage of dentition, and acrylic can be added for bite ramps as needed. A thicker material, Zendura 040”, is used for bruxers.

Banded Metal appliances

- The utilization of 3D printers for fabricating in-house metal appliances offers an opportunity to further enhance the capacity of the orthodontic lab. With the use of 3D printers, the fabrication process becomes more scalable.

- Software like Autodesk MeshMixer eliminates the need to remove excess model material around the molars with a handpiece. This not only increases efficiency but also simplifies the processing of banded metal appliances.

- We fabricate various metal appliances — Nance, rapid molar expanders, and lower lingual holding arch.

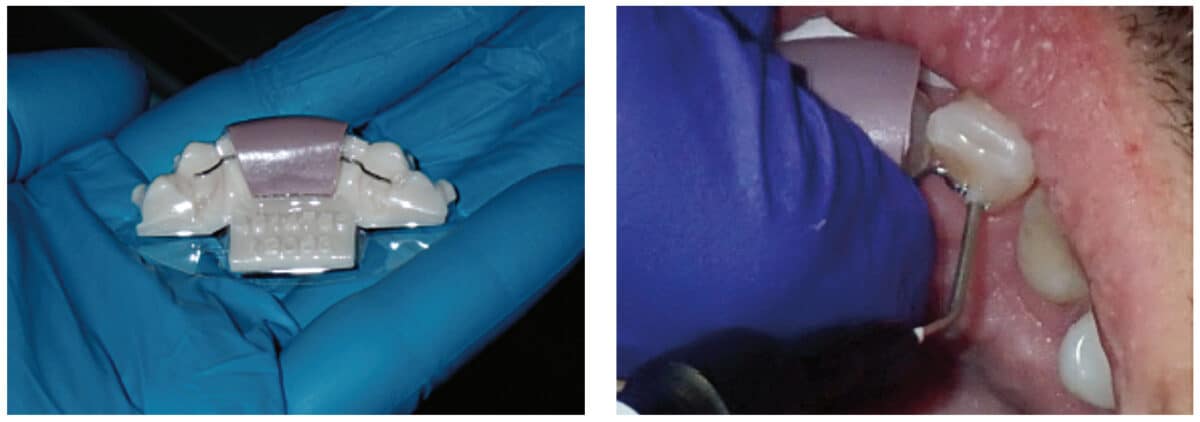

Fixed lingual retainer

- Although not made directly off a printed model, having a physical model (arch can be segmented and printed to save resources and effort) allows for fabrication of a jig. All the provider or assistant have to do is to place the jig that holds a fixed lingual retainer, bond and cure with flowable resin (Figures 4 and 5).

The extent to which an orthodontist incorporates 3D printing into their practice naturally depends on factors such as software, printing technology, available human resources, and importantly, their treatment philosophy.

Advanced implications of 3D printing

Although my office does not employ the tools below regularly, they are certainly generating discussions among orthodontists. It is important for orthodontists to stay informed about these advancements to explore their potential benefits and applications.

CAD/CAM-designed metal or resin appliance

- 3D metal printers are costly but will be a great addition if patient demand and volume are sufficient, and an in-house lab has the capacity to justify the purchase. 3D-printed, metal-banded appliances do not require separators, which saves providers’ and patients’ time and have great retention.

- CAD/CAM-designed resin appliances hold promise for significant implications in orthodontic settings, but further research, particularly concerning FDA-approved resin materials and protocol, is needed to fully tap into their future.

Direct-printed aligners and retainers

- Up until 2021, there were no marketed and approved materials specifically for direct printing of aligners — thickness of printed aligners was not transferred accurately as software design, and figuring out the post-curing process affecting resin property was not established.9 The AAO 2023 conference in Chicago featured presentations on direct-printed aligners, highlighting the introduction of Forastadent’s Graphy system — their resin advertised as the world’s first direct-print aligner material.10 A recent study conducted with their resin material, Forastadent Tera Harz™ TC-85DAP 3D Printer UV Resin, demonstrated improved accuracy and trueness of aligners compared to thermoformed aligners. Despite the buzz and excitement, we will need to see clinical studies to determine the viability of direct-printed aligners.11

Here’s some news on 3D printing from Braces on Demand and SprintRay! https://orthopracticeus.com/industry-news/braces-on-demand-3d-printing-software-for-orthodontists-now-compatible-with-sprintray/

References

- Tsolakis IA, Gizani S, Panayi N, Antonopoulos G, Tsolakis AI. Three-Dimensional Printing Technology in Orthodontics for Dental Models: A Systematic Review. Children (Basel). 2022 Jul 23;9(8):1106.

- Pereira ABN, Almeida RC, Marassi C, Abdo Quintão CC, Carvalho FAR. Do low-cost 3-dimensional printers produce suitable dental models? Am J Orthod Dentofacial Orthop. 2022 Jun;161(6):858-865.

- Frey S. Laser SLS vs DLP vs masked SLA 3D printing technology. The Ortho Cosmos. March 23, 2017. https://theorthocosmos.com/laser-sla-vs-dlp-vs-masked-sla-3d-printing-technology-compared/. Accessed July 13, 2023.

- Desktop Health. Desktop Einstein Pro XL Dental 3D Printer. https://health.desktopmetal.com/3d-printers/einstein-pro-xl/. Accessed July 13, 2023.

- Loflin WA, English JD, Borders C, Harris LM, Moon A, Holland JN, Kasper FK. Effect of print layer height on the assessment of 3D-printed models. Am J Orthod Dentofacial Orthop. 2019 Aug;156(2):283-289.

- McCarty MC, Chen SJ, English JD, Kasper F. Effect of print orientation and duration of ultraviolet curing on the dimensional accuracy of a 3-dimensionally printed orthodontic clear aligner design. Am J Orthod Dentofacial Orthop. 2020 Dec;158(6):889-897.

- Yoo SH, Choi SH, Kim KM, Lee KJ, Kim YJ, Yu JH, Choi YI, Cha JY. Accuracy of 3-dimensional printed bracket transfer tray using an in-office indirect bonding system. Am J Orthod Dentofacial Orthop. 2022 Jul;162(1):93-102.e1.

- Cowley DP, Mah J, O’Toole B. The effect of gingival-margin design on the retention of thermoformed aligners. J Clin Orthod. 2012 Nov;46(11):697-702; quiz 705.

- Tartaglia GM, Mapelli A, Maspero C, Santaniello T, Serafin M, Farronato M, Caprioglio A. Direct 3D Printing of Clear Orthodontic Aligners: Current State and Future Possibilities. Materials (Basel). 2021 Apr 5;14(7):1799.

- Forestadent®. https://www.forestadent.com/en-us/products/aligner/produktdetail/graphy-3/. Accessed July 13, 2023.

- Koenig N, Choi JY, McCray J, Hayes A, Schneider P, Kim KB. Comparison of dimensional accuracy between direct-printed and thermoformed aligners. Korean J Orthod. 2022 Jul 25;52(4):249-257.

Stay Relevant With Orthodontic Practice US

Join our email list for CE courses and webinars, articles and mores