CEU (Continuing Education Unit): 2 Credits

Educational aims and objectives

This self-directed educational course for dentists takes a look at various factors that can lead a practice to faster implementation and long-term adoption of new workflows in 3D printing.

Expected outcomes

Orthodontic Practice US subscribers can answer the CE questions by taking the quiz online at orthopracticeus.com to earn 2 hours of CE from reading this article. Correctly answering the questions will demonstrate the reader can:

- Identify how space in the orthodontic office needs to be prepared for 3D printing implementation.

- Recognize what types of training are necessary to ensure the long-term success of implementing clinical 3D printing technology.

- Realize how workflow changes with implementation of 3D printing.

- Realize some parameters for supplies for 3D printing.

Dr. Melissa D. Shotell discusses factors that should be considered before adding 3D printing to the orthodontic office

Orthodontics has long been on the cutting edge of digital technology in the dental field, and 3D printing is rapidly becoming an integral part of many orthodontic practices. There are many questions to be asked prior to purchasing a 3D printer, including evaluating what the office would like to 3D print, the software that will be used to design appliances, and what type of 3D printer and materials to purchase. Each of these questions can take substantial time to evaluate and answer for the individual practice. However, once the printer and materials are selected, the work toward implementation of 3D printing has just begun. The logistics of implementing 3D printing often becomes an overwhelming task if the orthodontist, team, and office space are not ready for this new technology. Taking a systematic look at several factors including the size and location of the 3D printing laboratory space, team training, and office workflow, can lead to faster implementation and long-term adoption of new workflows.1

3D-printing laboratory space

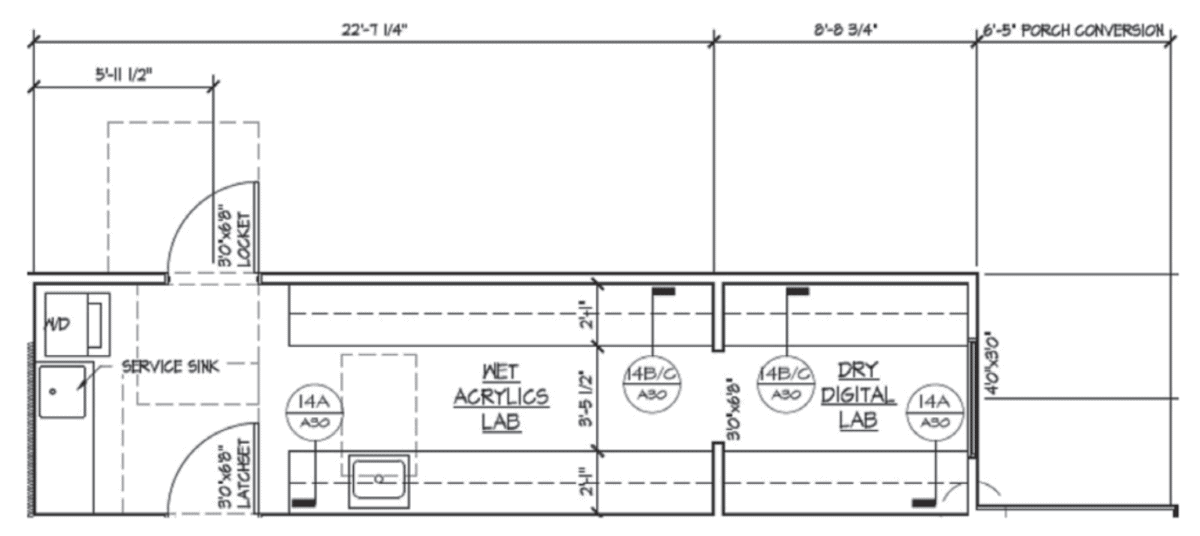

In many orthodontic practices prior to the use of 3D printing, the in-office laboratory was predominantly used for making stone models and minor repairs of appliances. For years, the practice trend was to send out stone models to commercial labs for fabrication of appliances, and with this, the laboratory often became small to allow for more clinical space. Now, with the implementation of 3D printing, larger laboratory spaces are required to house not only the 3D printing equipment, but laboratory storage of materials and appliances is required as well (Figure 1).

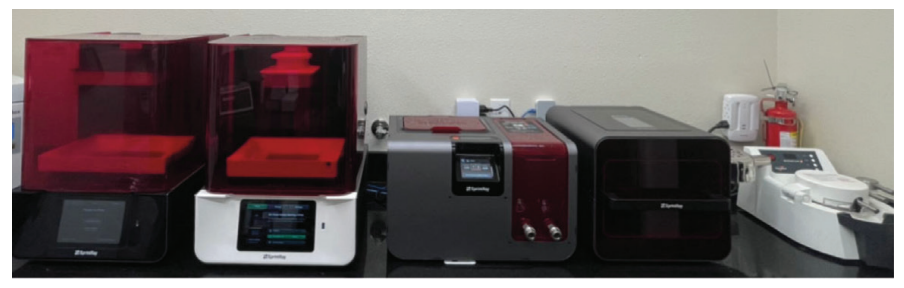

There has been a long-held misconception that adding 3D printing to an office is simply the act of buying a 3D printer. When 3D printing with many of the commercially available desktop-size 3D printers, post-processing of the dental models is required prior to use for the fabrication of orthodontic appliances. After the models complete the 3D printing process, they are typically removed from the 3D printer and rinsed in a series of alcohol rinses to remove uncured liquid resin from the models (Figure 2), and then the models are light-cured to complete curing of the model resin (Figure 3).2-3 This process requires additional specialized laboratory equipment beyond the 3D printer such as a wash station, curing box, and potentially vacuum-forming machine. Further, the laboratory must have the logistical space to support a 3D-printing ecosystem of equipment to both 3D print and post-process orthodontic models (Figure 4).

Team training and 3D printing

When adding a new clinical technique or clinical technology to an orthodontic practice, a large amount of focus is given to team training. This attention to training is important to ensure the long-term success of implementing clinical technology, so equipment does not end up going unutilized. It is equally as important to give this same amount of attention to team training in the 3D-printing laboratory. It is very easy to find many 3D printers collecting dust on a laboratory countertop because it is fast and simple to go back to the laboratory procedures with which all team members are familiar. Some practices will choose to utilize only a few team members in the 3D printing laboratory, and their training is critical for the success of 3D printing implementation. Cross-training and redundancy of staff members remains a critical part of workflow management.

The step-by-step procedure for 3D printing and post-processing should be covered for the printer system selected. Training in the 3D printing laboratory should consist of the proper handling techniques for uncured resin, and each printer system will have specific parameters for the curing of different resins. It is important to follow the post-processing directions closely to avoid introducing uncured resins into orthodontic appliances being fabricated. When following best practice recommendations of each printer system, there will be recommended routine calibration of the 3D printer to maintain accuracy, along with routine cleaning and maintenance. Team member training should focus on skills of 3D printing, but also the importance of maintaining the laboratory to ensure proper functioning of the 3D printer system. Key to management of the laboratory and digital machinery is maintenance of the calibration of the 3D printer to ensure consistent output for patient appliances. Further, ensuring expiration dates of 3D-printing resins is also an important part of this maintenance that many easily overlook, and some resins absolutely cannot be used beyond their expiration date.

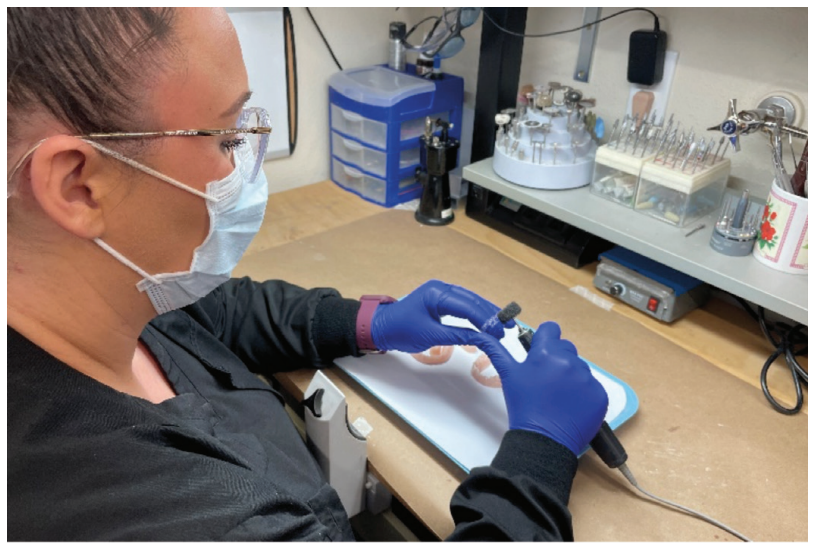

Many team members may find that they are drawn to one particular area of the laboratory process. Some may enjoy running and maintaining the 3D printer and post-processing equipment, while other team members may enjoy the fabrication of orthodontic appliances including clear aligners and retainers (Figure 5). Utilizing these natural preferences can help the team member to engage in the laboratory workflow, and can utilize their skills to improve the quality of lab appliances.

As an office expands the number of appliances they are fabricating, a system of laboratory organization can be utilized to ensure the appliances are completed on time for the patient’s appointment. Multiple software options are available for tracking lab work, but there are also simple organizational techniques such as having a white board or clip board with cases that need to be 3D printed or appliances fabricated.4 Laboratory storage can be a challenge in high-volume labs, and a system of lab case pans or hanging files can save space and keep individual patient cases organized. Determining a laboratory system of organization and assigning different team members to different areas of the laboratory can improve efficiency and optimize the laboratory workflow.

Office workflow

After the 3D printing laboratory has been set-up, and team members are comfortable with the basic laboratory procedures, the focus should become implementing 3D printing into the daily office workflow.5 Often the clinical aspect of a patient’s treatment will remain the same, but the timing of receiving appliances and the types of appointments scheduled may change. In the past, when sending appliances out to a traditional orthodontic laboratory, there may be several days from a patient’s initial appointment until receiving an appliance. As a result, many clinicians focus their use of 3D printing for same-day or next-day expedited orthodontic appliances. This allows for a streamlined clinical workflow and less work juggling or moving patient appointments because a laboratory had delays in production. To fabricate appliances quickly, however, there must be a seamless integration from taking records in the clinical space, to sending the appliances to production in the in-office laboratory (Figure 5). Assigning key team members to oversee the process of transferring records from the clinic to the laboratory and then initiating the laboratory workflow, will avoid delays between the patient’s records appointment and appliance delivery.

Summary

When evaluating to see if 3D printing is a good fit for an orthodontic practice, there are many factors to consider. 3D printing can greatly reduce the time that patients wait to begin treatment by bringing the laboratory process into the orthodontic office. However, there are physical size space requirements for equipment, and a new aspect of laboratory management that must be implemented. To ensure long term success of this workflow, it is important to consider many of the factors of team training both in the laboratory and clinical spaces and workflows. It is important to properly implement 3D printing to avoid the printer sitting idle on a countertop because there is not a workflow within the office to incorporate the use of 3D printing.

After reading Dr. Shotell’s article on 3D printing in the orthodontic office, read more about how she makes a positive impact on patients in her practice profile. https://orthopracticeus.com/practice-profiles/melissa-shotell-dmd-ms/

References

- Tian Y, Chen C, Xu X, Wang J, Hou X, Li K, Lu X, Shi H, Lee ES, Jiang HB. A Review of 3D Printing in Dentistry: Technologies, Affecting Factors, and Applications. 2021 Jul 17;2021:9950131

- Scherer MD, Al-Haj Husain N, Barmak AB, Kois JC, Özcan M, Revilla-León M. Influence of postprocessing rinsing solutions and duration on flexural strength of aged and nonaged additively manufactured interim dental material. J Prosthet Dent. 2022 May 19:S0022-3913(22)00222-0.

- Panayi NC. Directly Printed Aligner: Aligning with the Future. Turk J Orthod. 2023 Mar 21;36(1):62-69.

- Eliliwi M, ElShebiny T, de Menezes LM, Stefanovic N, Palomo JM. Comparing virtual setup software programs for clear aligner treatment. J World Fed Orthod. 2023 Apr;12(2):50-55.

- Revilla-León M. We Are A 3D Printing Generation. J Prosthodont. 2022 Mar;31(S1):3.

Stay Relevant With Orthodontic Practice US

Join our email list for CE courses and webinars, articles and mores

Melissa Shotell, DMD, MS, is a Board-certified orthodontist practicing in a multi-specialty practice in Sonora, California and focusing on the interplay of orthodontics and restorative treatment. After completing dental school, Dr. Shotell practiced as a restorative dentist for several years, then returned to school to complete a certificate and master’s degree in orthodontics from Loma Linda University. Dr. Shotell considers education to be her passion. She presents nationally and internationally on dental technology, is part-time clinical faculty at the University of Nevada, Las Vegas orthodontics department, and teaches in the CE department for the University of Alberta. Dr. Shotell also is the co-founder and chief clinical officer of Plus Orthodontics. Dr. Shotell shares tips and tricks on orthodontics and clear aligners on social media as alignerbee.

Melissa Shotell, DMD, MS, is a Board-certified orthodontist practicing in a multi-specialty practice in Sonora, California and focusing on the interplay of orthodontics and restorative treatment. After completing dental school, Dr. Shotell practiced as a restorative dentist for several years, then returned to school to complete a certificate and master’s degree in orthodontics from Loma Linda University. Dr. Shotell considers education to be her passion. She presents nationally and internationally on dental technology, is part-time clinical faculty at the University of Nevada, Las Vegas orthodontics department, and teaches in the CE department for the University of Alberta. Dr. Shotell also is the co-founder and chief clinical officer of Plus Orthodontics. Dr. Shotell shares tips and tricks on orthodontics and clear aligners on social media as alignerbee.