In this FAQ Special Section, Boyd Industries, Brius, Gaidge, and Specialty Appliances answer questions about what makes their equipment and technologies valuable to your business’ profitability.

Boyd Industries

Market leader for orthodontic operatory equipment

Why is Boyd operatory equipment and cabinetry better than the competition?

As the market leader for orthodontic operatory equipment, Boyd is best known for its ideal design and customizable features combined with proven quality and reliability. The company’s orthodontic products are the industry standard having been time tested over the company’s history by thousands of orthodontists around the world.

Boyd designs and fabricates the widest variety of cabinetry options to fit the size, functionality, and style of your office. The cabinetry line of standard and custom designs sets the company apart from others in the orthodontic industry. The company’s designers can adapt standard configurations or design cabinetry completely unique.

Do Boyd products meet all FDA and regulatory requirements?

Yes, our equipment meets all required regulatory standards for compliance. These include IEC 60601 safety standard for medical/dental devices, CSA for Canadian, and CE for European. The FDA granted clearance of Boyd’s dental delivery units having issued the company a Premarket Notification or better known as a 510(k) for use.

As an internationally certified, ISO 13485:2016 company, Boyd goes through annual independent audits by the British Standards Institute to assure we meet FDA, ISO, and all other regulatory standards.

What makes Boyd unique for orthodontists?

We pride ourselves on providing our customers with the latest technology and innovations in orthodontics. Our operatory products are ergonomically designed to reduce fatigue experienced in running an active orthodontic office, while constructed using durable materials to provide dependable service.

Does Boyd offer financing options?

Boyd has a very competitive program for recent residency graduates and separating military members, offering them significant product discounts or favorable payment terms.

What is the lead time for receiving Boyd equipment, once I place an order?

Despite the volatility of today’s global supply chain, Boyd has been able to better manage its lead times because of the company’s U.S.-based factory and North American supply base. Boyd’s factory fabricates steel, plastic, upholstery, wood, and many other components used in its products. The capability to directly manage much of the product content internally allows the company to maintain lead times to under 8 weeks.

Where can I see Boyd equipment on display?

Boyd attends industry trade shows to display and demonstrate equipment. In addition to trade shows, Boyd has a product showroom at our headquarters in Clearwater, Florida.

Interested in learning more? Please call our sales team at (727) 471-5072, email us at sales@boydind.com, or visit www.boydindustries.com/products/orthodontics.

Brava by Brius™ Technologies

Bringing transformative technology to orthodontics

Who is Brius™?

Brius Technologies is a forward-thinking innovation company dedicated to improving the orthodontic experience for both patient and orthodontist.

What is Brava™?

Brava by Brius is a completely new concept in orthodontic treatment — that of Independent Movers™. Brava is the only orthodontic system to provide simultaneous, independent tooth movement, a radical departure from traditional mechanics.

How is Brava different?

Brava is a fundamentally new way to move teeth — with Independent Movement. The movement of any tooth has little to no effect on any other tooth, so the reciprocal forces that cause unwanted side effects in conventional treatment and aligners are essentially nonexistent. Brava moves teeth independently, which results in highly effective and efficient treatment.

How does Brava work?

Brava leverages a digital workflow — digital scan, setup, and treatment plan approval by the orthodontist. Utilizing proprietary Brius Planner Software, precise force and moment are calculated for targeted tooth movement. Brava is then manufactured and delivered to the office.

The Brava system includes custom brackets loaded into digital bonding trays and Brava, which consists of an anchorage base and flexible NiTi arms that connect independently to each tooth via the custom bracket.

As teeth move, their reactive forces translate to Brava’s anchorage base, which then dissipate along the entire arch. With clinically insignificant reactive forces, Brava’s Independent Mover technology puts each tooth on an independent path to its planned position.

What are Brava’s key features?

- Brava’s optimized biomechanics result in esthetically superior, personalized, convenient, and highly effective treatment.

- The entirety of Brava’s tooth movement is programmed into a NiTi device, active throughout the course of

- With Brava, there are no wires and no need to wait for larger archwires to start A/P correction as with traditional braces. With Brava’s Independent Mover Technology, A/P correction can be started from the outset of treatment, maximizing treatment efficiency.

- There is no limit to the types of cases Brava can treat.

To learn more about this exciting, technological revolution, visit www.brius.com.

Gaidge

How often do practices look at their data?

Many practices use Gaidge to look at their data every day — and it makes sense, given the critical business insights easily visible within the software. Looking at 80-plus orthodontic metrics and 35-plus key performance indicators can be transformative; it brings granular data to life and broadly illustrates the successes and downfalls often overlooked in manual analyses. Visually comprehensive data also allows orthodontic teams to set annual goals with an easy glance at monthly and quarterly trends.

When should a practice start using Gaidge?

Gaidge is extremely valuable for orthodontic businesses in every phase of the growth process, as it isn’t just limited to those with higher revenue. Every practice needs a clean, solid data foundation regardless of age. Brand-new practices can use Gaidge’s analytics to look for areas of improvement and opportunities for growth. With time, Gaidge compiles their historical data, so they can view a year-over-year (YOY) comparison.

How do I know how my practice is performing in comparison to other practices?

Gaidge not only compares the data of multi-location practices, but also showcases regional comparisons with built-in industry benchmarks. Together these features allow practices to compare themselves to regional counterparts and adjust where it’s needed.

What do you do with the data?

For an orthodontic practice to thrive in a competitive and often challenging market, it must be future-oriented and up-to-date on its data. Gaidge provides access to valuable growth metrics, so practices can set and exceed goals. With this insight, orthodontic offices can measure their effectiveness by viewing every step in the patient’s journey from New Patient Adds to Treatment Efficiency. These details are important because they reflect the business’s overall health and allow teams to move forward with a data-driven strategy for growth.

How do I best use Gaidge with my team?

Gaidge considers every aspect of an orthodontic practice, and running any business involves a clear understanding of its data. How else will practices know if they’re meeting their goals? Financial Coordinators can ditch their spreadsheets — which are time-consuming to update — to analyze revenue metrics like Productions, Collections, and A/R & Delinquency. With treatment efficiency tracking tools, doctors can strategically track patients’ treatment journeys, provide accurate treatment time estimates, and establish patient trust. Gaidge has dashboards for every role in your office to provide accountability and to ensure that your team isn’t spending valuable time manually pulling and analyzing data.

To schedule a demo, visit www.gaidge.com/demo.

Advances in orthodontics: 3D-printed appliances

What technological advancements have had the greatest impact on orthodontic laboratories recently?

There have been many technological developments in orthodontic laboratories in the past 2 decades. Intraoral scanning has gone from being a limited-use item to the industry standard — facilitating substantial advancements in the laboratories. We now have 3D printers, 3D wire-bending machines, and CAD/CAM software to help with multiple areas of workflow and the digital design of complete appliances.

Are traditional and printed-metal appliances designed differently?

The designs are identical on permanent dentition. On mixed dentition, bonding pads to the lingual of the teeth can be used for added retention. For example, when fabricating a palatal expander for a patient with short clinical crowns, adding lingual bonding pads to the deciduous molars will provide more retention than lingual extensions.

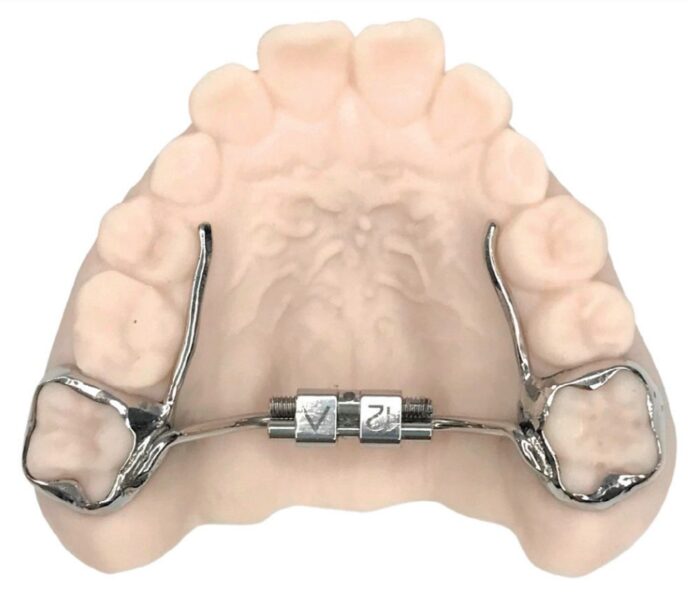

What are the advantages of printed-metal bands and appliances?

The biggest advantage is the elimination of separator appointments. The bands are designed on the buccal and lingual of the clinical crowns and are attached only through the occlusal embrasures, making tooth separation unnecessary. Other advantages include improved fit as bands are designed to the scans, no blanching of the tissue, and easier delivery and removal.

What is the bonding procedure for printed bands?

While the delivery of printed bands is similar to that of traditional bands, there are notable differences in the bonding protocol. The recommended procedure begins with etching the areas to be bonded, which are bands and any bonding pads. Next, apply a bond enhancer, such as Assure®, and utilize Band-Lok® Plus adhesive. The areas to be etched and bonded are easily identified by the bands or bonding pad areas. Retention depends on the bond strength achieved during delivery.

Are printed bands stronger than traditional bands?

Traditional bands are made from stainless steel, while printed bands are generally made of cobalt-chromium, a stronger and more durable material. Cobalt-chromium can be printed as small as 0.004 inches, offering great versatility in appliance design.

Are there limitations on what appliances can be printed?

Currently, all metal appliances can either be fully printed or have traditionally bent wires attached to printed bands.

Visit us at www.specialtyappliances.com.

Did you miss our AAO Special Section? There’s still time to read about equipment and technologies that can benefit your practice by clicking the link! https://orthopracticeus.com/aao-special-section/

Stay Relevant With Orthodontic Practice US

Join our email list for CE courses and webinars, articles and mores